for further tips to help with construction

of this project.

Assembly.

Start with the resistors, install R1, (4K7) Next R2 And R3.

Next install the FET transistors Q1 and Q2. If you plan to fit any

heatsinks to these FET's then you will need to source these first as

they do not come with the kit and it is best to leave them out for now

until you get the heatsinks, then put each FET onto the heatsink first,

and then install them onto the PCB.

The reason doing it this way is to make sure the height of the FET's

legs are correct when fitted. When using a heat sink, you will also need

to make sure that the heatsink does not short out on any components

installed.

Optional extra. If you want to add a switch SW1. I fitted a switch

on my kit and soldered header pins on the switch, before soldering to

the board. (The switch SW1 and header pins are Not Supplied with the

kit.)

If you do not wish to add a switch, then you will need to fit a shorting

link or jumper in place of the switch.

Fuses

The blade fuses are also not included with the kit. You can go to most

dollar outlet shops and buy them. Our local dollar shops in town have

them for around $2.50

I used a 30A in F5 as I used J5 powerpole for the 12v power in. If

running HF rigs I fitted a 25A and 15A on VHF radios. This of course

needs to be rated on the current drawn from your radio so your fuse may

be higher or lower.

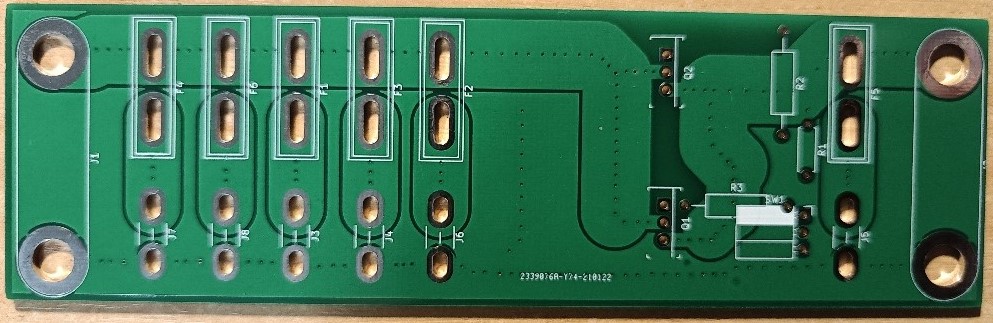

Photo 1.

Shows the blank PCB board before assembly. If you do not want to fit

LED's then skip the LED modification

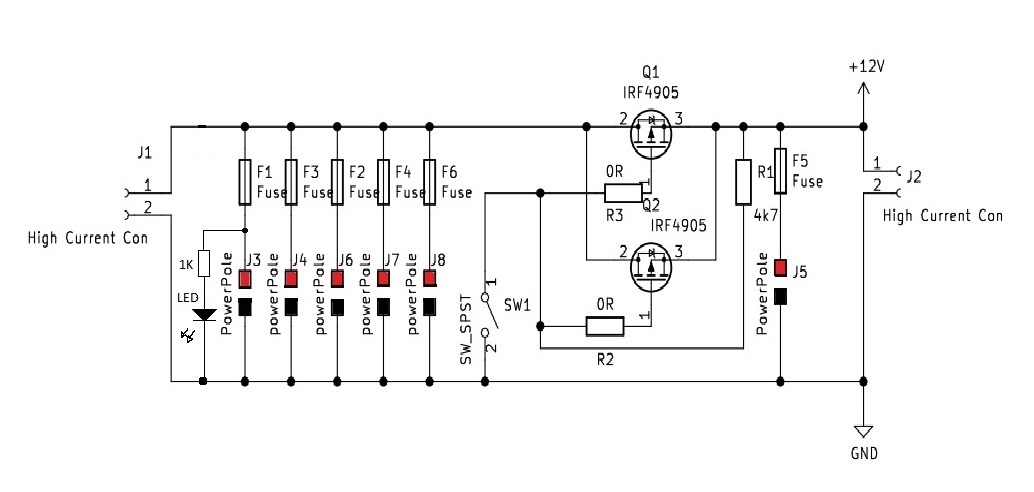

Circuit Diagram

Photo 2. Shows the circuit diagram.

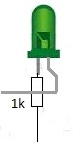

LED Modification.

In the circuit diagram you will notice a 1k resistor and LED at the

junction of J3 and F1. If you decide you want to fit these LED's then

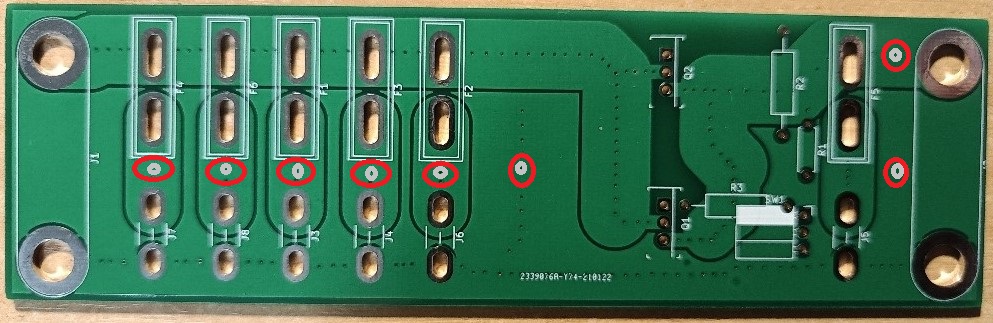

you will need to modify the PCB board as shown in photo 3.

On the PCB board in photo 3, highlighted in red, you will see 3

chevrons, drill the center chevron as shown. Use a 1mm drill and once

drilled you will now need to remove a small part of the green paint

just around the hole you just drilled to allow solder to flow once you

fit the resistor.

I have shown this as a silver colour, inside the red rings that you

need to remove. Try not to scratch too much paint away and try to keep

it around the hole only, so once soldered it looks nice and neat.

The circuit diagram is showing only one LED. You need to add one LED for

each of the power poles.

I added the green LED's to show that the circuit is working, if the LED

is on. If one of the LED's goes out then the green LED that is not lit

will mean the fuse is blown. You could do the opposite and fit maybe a

red LED across the fuse which would only then light up if the fuse blows.

(This is not shown)

Photo 6. shows how each LED is fitted. the anode of the LED is joined to

the 1K resistor and fits through each hole drilled. The cathode's leg

gets bent as shown in photo 6, so the bent leg joins onto the next LED

and so on. When you get to the last LED, the connection to earth can be

seen in the middle of photo 7. I also added heatshrink over each of the

1K resistors.

The stand alone LED's and 1K resistor for F5 is

mounted differently to the rest of the LED's. Make sure you get it

around the right way. Mount the cathode leg of the LED straight down to

earth so it is inline with the other LED's and fit the 1K resistor to

anode, and the other side to the junction of F5, R1 and pin3 of Q1 and

Q2.

Anderson 25A Power Pole.

When you go to assemble these, you will need a suitable wire to solder

to the pin and to the PCB. I used the inner conductor from some RG8 coax

cable as this was a perfect size to use. Slot together the red and

black plastic power pole connectors. Next solder the wire to the pin and

fit each pin into the plastic housing. I used two lenghts of the inner

conductor, one for the red and other for black. Do one pair at a time

starting at one end and work your way over, making sure these are flat

on the board.

Reference numbers are J5, J8, J7, J6, J4, and J3.

Trim the wire, and repeat the same process for all the power poles.

Make sure you get the red and black connectors the right way round. See

photo 5, for a close up view.

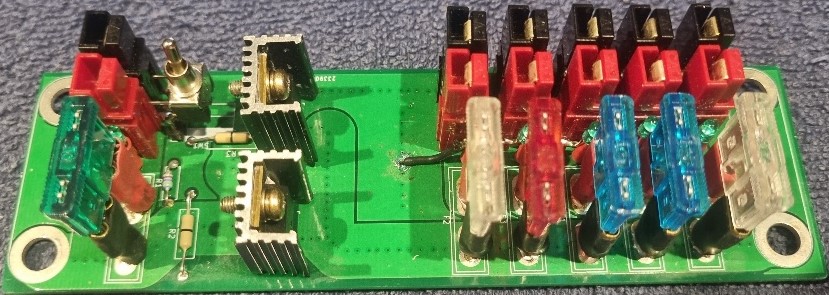

Spade Terminals.

With the spade terminals we will use these as the fuse holders.

Using a pair of pliers squeeze and crimp the tip of the cable side end

so that it fits into the PCB. Also do these in pairs, and to keep these

straight, using a blade fuse while you solder them in place.

Push and fit the spade terminal onto the fuse and insert it in to F1

and solder each spade terminal onto the board. Remove the fuse and do

the same again for the rest F3, F2, F4, F6 and F5. You should now end up

with it looking like the finished unit in photo 4.

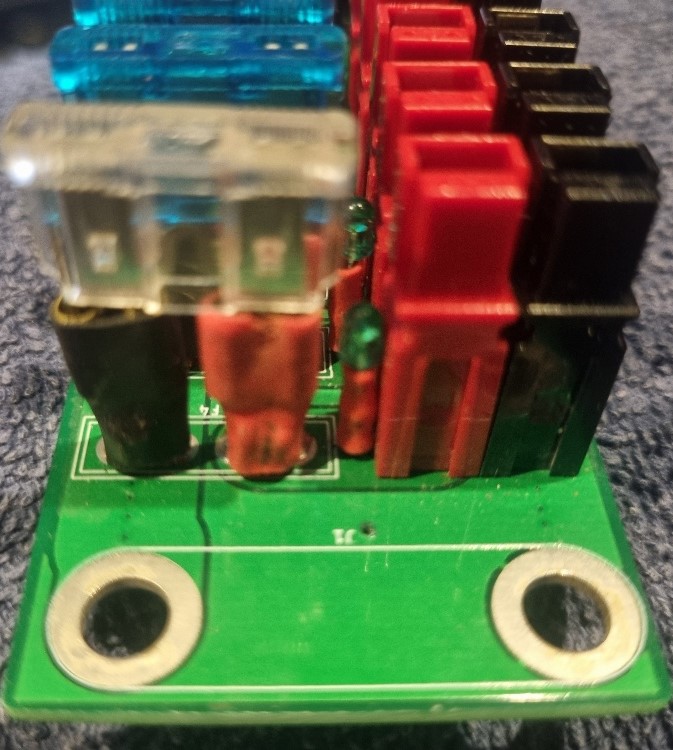

End View of Board.

In photo 5 you can see a close up end view showing the spade terminals

and blade fuse inserted. I added heat shrink over the terminals. I used

red and black heatshrink as I did not have enough red shrink for both

terminals. Being a fuse both sides of the fuse will have 12v when the

fuse is good.

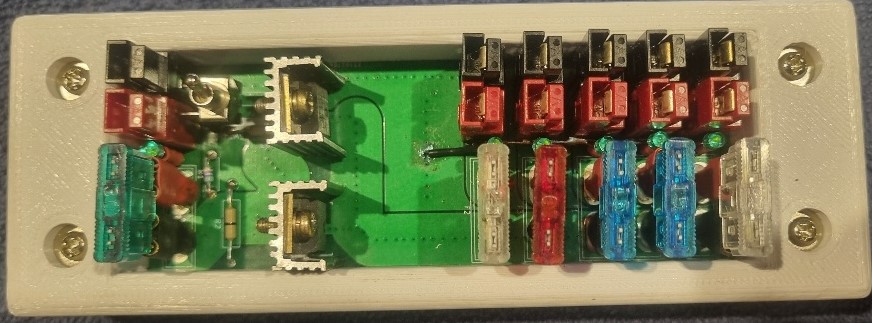

Completed in Case.

Photo 7 shows the finished project in a 3D printed case. Credit goes to

Jack ZL1IJ for design and of printing these cases.

Any issues or questions or help needed, you can email myself ZL1RJS or

David ZL1DK below.

Contacts

ZL1DK

Just click on the callsign to email David

ZL1RJS

Just click on the callsign to email Rob

Photo 1. - DC Switch Blank PCB.

Photo 1. - DC Switch Blank PCB.

Photo 2. - The Circuit Diagram.

Photo 2. - The Circuit Diagram.

Photo 3. - Blank PCB showing marking to drill.

Photo 3. - Blank PCB showing marking to drill.

Photo 4. - Complete Assembly.

Photo 4. - Complete Assembly.

Photo 5. Side View.

Photo 5. Side View.

Photo 7. Completed in Case.

Back to Top

Photo 7. Completed in Case.

Back to Top