SOLDER BASICS &

CONSTRUCTION TIPS

See the full pdf version here How To Solder Beginners Guide This

guide was made by Makerspaces

and I take absolulety no credit for this soldering beginners guide in

these links.

Disclaimer

Before I begin with a few personal soldering tips, I would like to point

out a few things. So before we go any further, Please make sure you read

my

Disclaimer

and that you fully understand it.

This link to the basic soldering guide above refers to the the USA mains

voltage of 120v where in New Zealand our mains voltage is 230v. For

safety, always pay attention to the operation voltages of any equipment

that you plug into 230v or purchased outside of New Zealand. The USA

also uses imperial measurements and some tempertures are in °F

Getting Started

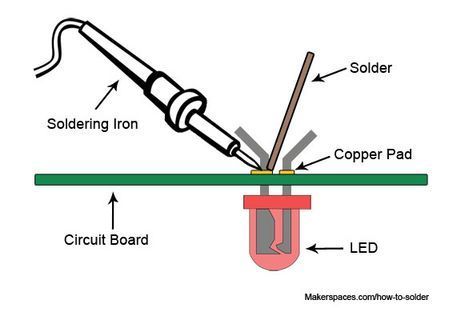

The basic soldering guide by makerspaces is a beginners guide and refers

to single sided through hole components PCB's as shown in photo 1, hence

a basic guide. It is a great guide to help get you started and if you

are just learning how to solder and even to refresh your soldering

skills. It is a lot of fun once you get the hang of it.

Although it is hard to teach soldering skills, it is really down to the

individual to practice and practice some more. It can become easier as

the more time you spend in construction, hopefully you will become

better and better at it. Good luck.

The basic soldering skills still applies to all construction work.

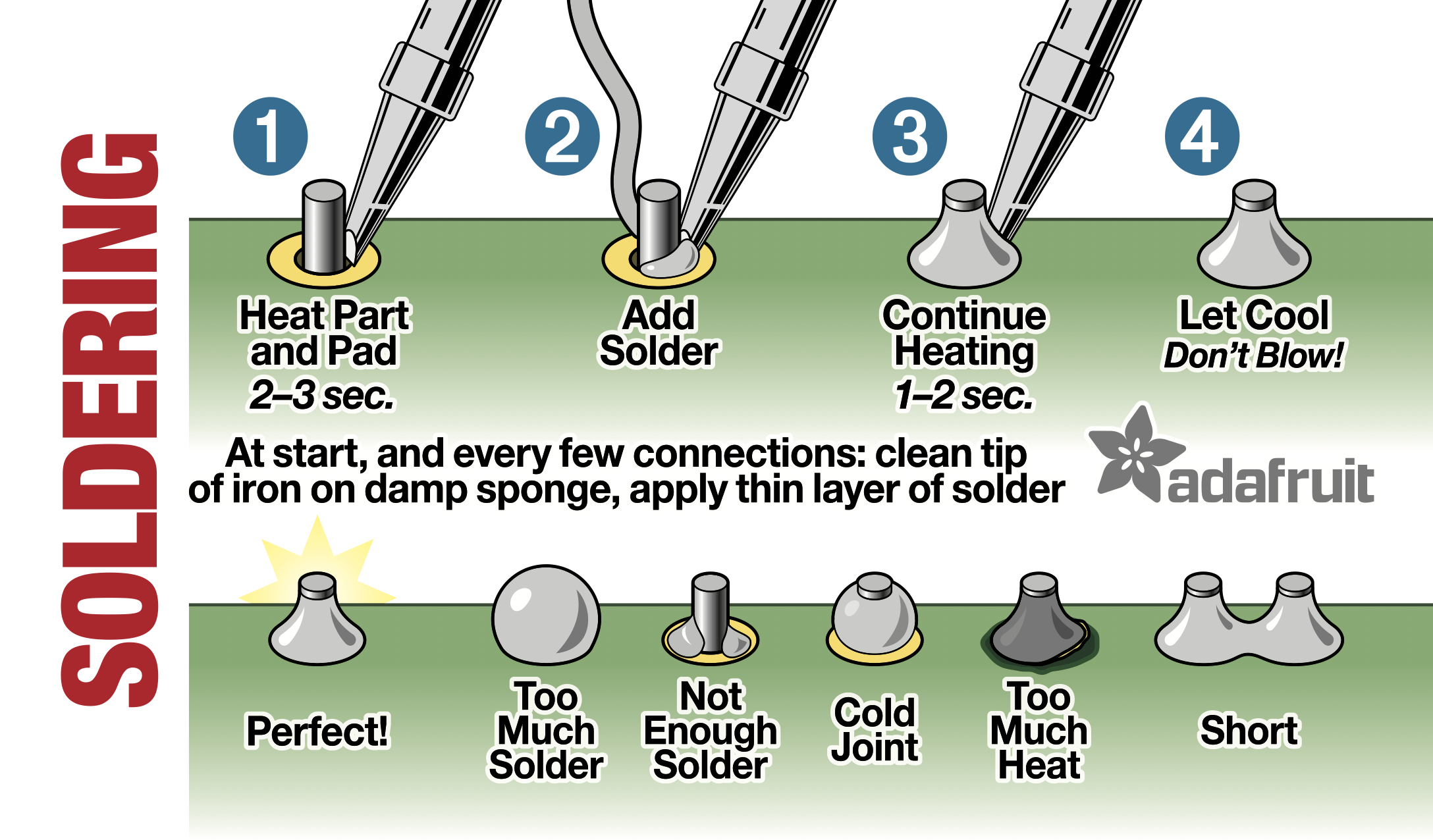

See photo 3. This shows you in 4 steps the process on how to solder.

I will explain more on these steps, so keep reading.

Printed Circuit Board Types

In electronics, SMD stands for Surface Mount Device, a type of

electronic component designed to be mounted directly onto the surface of

a Printed Circuit Board (PCB).

Unlike through-hole components, which have leads inserted into holes

drilled into the PCB, SMDs are soldered directly onto the surface.

This technology supports Surface Mount Technology (SMT), SMD's are a lot

smaller over through-hole components thus making the circuit design much

smaller.

The boards we are using in our club projects are 2 layer PCB's or double

sided, through-hole and surface mount components (SMD) and with

construction of these types of PCB's can have a few different methods to

think about when fitting the components.

Basic Soldering

Prepare the area

Ensure the work surface is clean, dry, and free from debris and no

fingerprints on the area you are about to solder. The grease from our

fingertips can cause the solder not to flow, thus may cause a bad

solder joint.

Using the right solder

Select a solder alloy suitable for your application (e.g., 60/40

tin-lead, 95/5 tin-silver, or lead-free). Your choice here as long it

has flux... Flux ensures that the solder flows wholly and evenly around

the joint, which is necessary for a strong and reliable electrical

connection. With most solder you buy today it has the flux built into

it. There are however solder's that have no flux which I do not

recommend. Things to be aware of is the thickness of solder.

Remember the thicker the quicker it fills the joint and in some cases it

can leave lots of unwanted solder and burnt flux on the PCB and this

appears as a brown colour.

I recommend to use a thin solder for light SMD construction work like

0.71 to 1mm

Unfortunately flux is required for flow to get a good joint, but it

leaves a residue behind that we do not want. It can lead to current

leakages and even short out so flux can become a unwanted problem.

It will over time oxidise the joint, causing issues. We can fix this by

cleaning off the unwanted flux. One method to clean flux is to use

Isopropyl alcohol and using a Q-tip (cotton bud) or a old tooth brush

to clean the PCB and dissolve any unwanted flux.

Setting up the soldering iron

When constructing, I recommend that you use a temperature controlled

iron. This can be adjusted and allow the iron to operate at the correct

operating temperture.

There are quite a few different types of temperature controlled

soldering irons. These can show a digital readout of the temperature or

dials that will adjust to the operation temperature and can have

flashing LED's when the correct temperature is reached.

Desoldering stations that can remove components like hot air guns, and

desoldering stations that suck the solder off the PCB.

These can also be expensive to buy but cheaper devices that also work

just as well are the standard hand solder sucker or solder wick.

Solder wick is a copper braid, normally on a roll, which when heated

over the pad, will remove any excess solder and the un-wanted solder

will transfer on to the braid leaving very little solder on the board

or pad and allowing you to either remove the component or the unwanted

solder or both.

The braid will now have the unwanted solder, cut off the used braid

ready for the next component you wish to remove its solder from.

Plug in the iron and adjust the temperature according to the solders

alloy and your personal preference (This can be typically between 300°C

to 420°C). This also depends on the melting point of the solder and

application as some solders have a low melting point. When using a

soldering iron stand, make sure that it has a heat-resistant holder.

This will allow the iron to maintain the temperture it is set too.

Beware of cheap wire stands that do not have heat-resistant holders,

the iron will heat up the stands holder and stop the soldering iron to

run at the desired temperture, plus these cheap stands could also burn

you if touched. I do NOT recommend these stands as your iron will not

be working at the correct temperture when you go to use it.

Ready to Start Soldering

Melt a small amount of solder onto the tip of the iron. This is called

“tinning” the iron. This is done to stop the tip from oxidizing which

will repel solder and means the tip is in bad condition and gives a

poor heat transfer. A tip with solder means it is in a good condition

and will have good heat transfer. Clean the tip before use to wipe off

excess solder.

- Step 1.

Applying the Iron to the component and pad.

Heat the component and pad together for approximately 2 - 3 seconds.

- Step 2. Applying the Solder.

Always make sure that you apply enough heat! to both the pad and to the

component. Otherwise, you might end up with a cold solder joint. as

shown in the lower half of photo 3. Add enough solder to make the joint

to cover the pad and component. When applying solder, apply it to the

component leg or pad and not directly on to the iron. This is to ensure

both the copper pad and component gets soldered. See photo 1.

- Step 3. Applying heat.

Touch the soldering iron to the joint, allowing the solder to melt and

flow between the component and pad. Keep the iron in place until the

solder has flowed and formed a strong bond. Around 1 - 2 seconds.

Adjust the iron’s position as needed to ensure a good clean joint.

- Step 4. Let it cool down.

Once you have solder flow, remove your iron and let it cool down. Do not

blow on to the joint to help it cool. This can result in cold joints.

These 4 steps above, should take around 6 to 10 seconds on each leg

using standard components.

Examples of soldered joints / How to correct.

If you have applied the 4 basic steps above, then you should have, and

see a perfect result each time.

Poor soldering skills will result in different bad joints as shown in

the lower half of photo 3, and depending on your timing when soldering.

As in the photo, examples are shown, and listed below. These are:-

- Too Much Solder.

- Not Enough Solder.

- Cold Joint.

- Too Much Heat.

- Shorted joint.

To go through the list,

Too Much Solder,

Ends up in a blob and happens when to much solder has

been applied. Correct this by removing the excess solder and re-apply

with fresh solder if required.

Not Enough Solder,

Means you have either, taken your iron off too soon or not applied

enough solder to flow. In the lower half of photo 3, in the example,

you can also see the pad has not been heated enough and very little

solder applied for solder to flow on to the component and the PCB's pad.

Refer to and repeat the process in step 1. plus leave the iron on the

pad for a bit longer until the solder has flowed to obtain a perfect

joint.

Cold Joint,

In the example of photo 3, it shows a blob of solder and a poorly

soldered joint, also the pad and component has not had the correct time

or heat to the pad and component to bond together. The example shows

that the components leg has been soldered but poor heat transfer from

the component to the PCB's pad. To correct both these types of joints,

apply your iron for a little longer or raise the temperture of your

iron. Repeat and follow the process in step 1. and leave the iron on the

pad for a bit longer until the solder has flowed to obtain a perfect

joint.

Too Much Heat,

In the example, it means you have left your iron on the component for

way too long. You can see that the joint has changed colour and has

excess flux. Avoid leaving your iron on any component or pad for too

long as this can damage the component or PCB. If you have heated the

component and it is not wanting to flow due to high heat, try applying

fresh solder, so the flux in the new solder will help to make the joint

flow. This can result in too much solder on your PCB but if that

happens, refer back to, how to remove access solder.

Shorted Components,

This can be caused by a few things. Applying too much solder or by

having the wrong size tip on your soldering iron causing you to heat up

two pins together. Another cause may be that your soldering iron is too

hot and the temperature needs to be lowered.

Most times it can be having your iron to close to the other components

pad and allowing both to join together. It is very important to pay

attention and not to short out tracks or components when constructing.

Man made, or Woman made faults can be very hard to find.

How to Remove Excess Solder

To do this you can use any of the following.

- Desoldering iron.

- Solder-wick.

- Solder sucker.

I have them all and I will use which ever I think is best suited to

remove unwanted solder. Mentioned above, this can be from, to much

solder or you are removing the component.

Additional Tips

Use the right soldering iron tip: Choose a tip, suitable for your

soldering application (e.g., pointed, flat, or chisel-shaped tips).

These tips do make a difference when constructing. I perfer a small

chisel tip which I find works for most soldering work.

Always refer to your soldering iron manual and manufacturers

instructions.

Keep the Iron Clean

Regularly clean the iron tip and handle to prevent oxidation and ensure

proper heat transfer.

Work in a well-ventilated area: Soldering can release fumes and

particles, so ensure good airflow and avoid inhaling them.

Use safety precautions: Wear protective gear, including gloves,

safety glasses, and a face mask, when soldering.

Practice makes perfect: Start with simple projects and gradually

move on to more complex ones as you gain experience and confidence.

As you become more experienced your soldering skills will become second

nature.

Construction Tips

Installing Components

Before you start soldering components on to any PCB, please read this

section first so you can pick up tips, without making mistakes, which

can or may be hard to correct later.

When installing any component, install and bend each leg over to hold

them into place on the PCB. This is to stop them falling out when you

turn over the pcb to solder, but before you solder and trim cutting the

legs close to the PCB, see my tips on

Bending of legs.

Prepare and install the component you want to solder. Before you solder,

check if the component has any polarity marking and that it is around

the correct way. Check it is the correct value. It is very important to

pay attention to detail to achieve high-quality solder joints and

workmanship.

Some components are static sensitive so pay attention to Electrostatic

Discharge (ESD) and only handle these components when installing them.

If you want to know more information about ESD, then I would suggest to

search ESD and how to prevent damage when installing and removing

components. Search Anti-static wrist straps, also.

Intergrated circuits, (IC's) When you insert IC's onto any PCB to

firstly make sure all legs of the IC are through all the holes, and that

it is also installed the right way around.

A good way to hold IC's in place is to solder pin one first, then solder

the last pin on the opposite side. This varies due to the size of each

IC and how many legs it may have. Check to see it is flat and fully

seated on the board before you solder the rest of the pins. It is easy

to correct now if there is any problem seen.

With surface mount IC's do the same only solder ONE pin to make sure it

is aligned and centered. Check that the IC has equal pads to solder on

both sides and if any problem, adjusment can be made before you continue

to solder the rest of the legs.

When installing resistors, you can install and bend each leg over,

before soldering see my tips on bent over legs, before you solder. Make

sure it is fully seated and it is flat on the PCB.

When installing capacitors, it is very important to make sure that these

are the right way round as some capacitors do have a polarity. These are

called electrolytic capacitors and normally have the negative marked on

them. With the non polarized capacitors, I like to install them facing

outwards and showing the value, so it is easily seen when beside

other components which can hide the value.

When installing diodes, again check alignment and polarity. Diodes have

a line marking on one side which represents the cathode.

Installing Transistors. These have 3 legs or terminals on them, called

emitter, base and collector. They can be NPN or PNP types and they come

in various pin configurations, so when installing these, to make sure

you have the correct transistor and its legs are installed the correct

way.

Components that are not fully seated, for example, a tact switch that is

not fully seated on the board can lead to failure by the track breaking

when the switch is pushed down, pushing the track away from the board.

If you have already read "Bending of the Legs" you can

Skip Here

Bending of legs

Refering to photo 1, you will see the LED component has bent legs and is

about to be soldered.

Bending of the legs can be a good thing but it

is done to stop the component from falling out once the board is turned

upside down to solder it. A lot of constructors like to install all the

components this way and solder them in all at once.

I recommend to install components a few at a time, starting with the

smallest and install all the same value components first (e.g. all the

1K resistors and then all the 10K and so on) plus only fitting a few

components at a time so not to overcrowd the PCB when ready to solder.

Over crowding components will simply cause the other legs to get in the

way while soldering.

Bending of legs is not much of a problem on single sided PCB's but be

aware when using two sided or multi layered printed circuit boards

(PCB's). Bending over of the legs on double sided PCB's can cause an

issue later on if the component goes faulty and you need to remove it.

When heating up and soldering the joint the solder's flux will flow

through the PCB to the upper side also, so now, not only do you have

both sides soldered, and bent legs, it will become very hard to remove

the component for whatever reason.

You will need to straighten the legs and remove the solder from both

sides of the PCB which I can assure you it is not an easy task and can

result in damage to the PCB. Once the faulty component is removed it is

possible that the track between the top layer and bottom layer may have

been damaged to the upperside of the PCB so when refitting check

continuity ot the track with a ohm meter.

To overcome bent legs, I recommend and what I do is to solder the

bent leg on ONE side only first, so the component now can't move or fall

out of the board. Straighten up the leg on the other side of the

component you are soldering and as it can't move, plus check and make

sure the component is flat on the PCB board. If all ok solder it. Then

come back to the bent leg you just soldered first and while re-heating

the joint to straighten up that leg making sure it is still seated

correctly afterwards, so the end result will be flat and neatly

installed. You do this to all the components, so now you do not have any

bent over legs. You can now trim the legs and cut off close to the PCB.

It is your choice if you wish to do this, but I think of a service point

of view and this will now make it easier to service later if you ever

need to work on it. I prefer to fit a few components at a time and with

resistors. As I have said I like to install all of the same value

components first so if you have 8x 1k resistors install them and then

move on to the next resistor value etc.

Another tip is to install all the smaller components first that are not

going to get in the way of others especially SMD components. With the

larger items work from the inside to the outside of the PCB to avoid

damage to the components already installed. Remember think smarter not

harder.

When installing SMD components, you will also need tweezers to hold the

SMD in place while soldering on the board.

Go back to previous and

Continue Reading

Oxidised Components

Sometimes components found in your junk-box may be a bit older when you

go to use them. What you can find is that the lead of the component is

of a dull apperence and may require cleaning prior to installing,

otherwise it may not have a good soldered joint and a cold joint is

formed. Over time in older components the leads of components can

oxidise and happens with most resistors and capacitors.

Clean the lead of the component, by using your side cutters, get the

component lead and placing the cutters at the top of the component and

gently squeeze and pull the component. Don't squeeze the component to

hard otherwise you will cut the leg instead and not clean it. This will

scrape off any oxidised coating leaving a shiny lead which the component

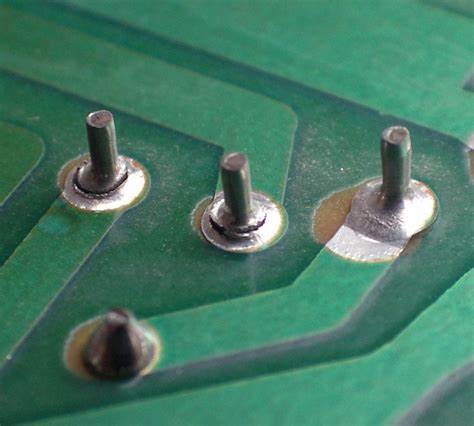

will now be good to solder. A cold solder joint often looks okay at

first glance. But when you look more closely, you’ll see that there’s a

tiny gap or crack between the solder and the leg, as seen in photo 2.

This example shows a cold joint / dry joint that the leg is not properly

soldered and can happen over time. This means, it has a poor or no

connection between the pad and component which can lead to intermittant

problems and even component failure when it goes open circuit and as a

result can cause damage to the circuit.

This can lead to some serious frustration when your circuit doesn’t work

and you are trying to figure out why.

Common Mistakes to Avoid

Insufficient heat

Not enough heat can lead to poor solder flow or incomplete joints known

as dry joints or cold joints. Normally a bad or dry joint can appear as

a dull look to the joint or cracks around the leg of the component.

See photo 2.

A good soldered joint has a shiny look to it. When lead

free solder is used a bad joint is not easily seen as this type of

solder gives the appearance of a dull finish.

Excessive heat

Too much heat can damage components, tracks, the PCB or create uneven

joints. Most PCB's today are made out of fibreglass so excessive heat

from heat guns can easily damage these boards.

Incorrect solder application: Applying too much or too little solder

can result in poor joints or excess solder causing blobs can disguise

cold or dry joints. It is therefore very important to ensure good heat

transfer.

Inadequate cleaning

Failing to clean the iron and work surface can lead to oxidation and

poor solder flow causing dry/cold joints. When trying to remove

components. This can be tricky as you can heat the board and the

component will not budge and you can end up damaging the PCB by

applying too much heat to the board. Removal can be achieved by applying

fresh solder that has flux and once flux has flowed it should be easy to

remove. Sounds strange to add more fresh solder and possibly you may end

up having excess solder. You will then use either solder-wick or a

solder sucker to remove the excess.

Resources

Online tutorials and guides, can be sourced on google and possible on

youtube video's showing you what they do. For more basic soldering info.

Visit this link

How To Solder

Look for online forums and discussion groups for makers and hobbyists.

Remember to always follow safety procedures and guidelines when

soldering, and practice patience and most of all attention to detail.

Remember, There is no rush in constructing any project, work at your own

pace. Just remember to check and double check your work.

I hope that this artical has helped you to become confident in soldering

skills.

Photo 1.

Photo 1.

Photo 2.

Photo 2.

Photo 3.

Back to Top

Photo 3.

Back to Top