TAIT 8100 VFO

INTERFACE

PROJECT

by Keith Dix ZL1BQE

This VFO interface kit is another kit designed by Papakura Radio Club

member, Keith Dix, ZL1BQE.

Full credit goes to Keith for the design. This VFO kit will plug

into the DB15 connector on the back of the Tait 8100.

These kits are available from David ZL1DK. Cost of each kit is $125.00.

(subject to change)

Email.

You can contact David directly via email on

ZL1DK

Just click on his callsign to email your interest to David.

Please note, I take no credit for this project and please read my

Disclaimer

and you understand it before

continuing.

Description of This Project:

Tait 8100 Series VFO Kit with 99 Memories.

This is a VFO unit that has been designed for Ham use and incorporates

most of those facilities that we would experience with a commercially

built radio from Icom, Yaesu, Kenwood etc... The software has been

designed to take 99 programmed memories.

This VFO unit will ONLY work with either the VHF or UHF Tait 81xx series

radios. You tell it which one you are using, so if you have both version

radios, you will need two of these kits to assemble. One for each radio.

The repeater shift is stored during this initial setup function. 600kHz

for VHF and 5MHz split for UHF.

There are 99 memories all stored in the VFO unit and not in the radio’s

software, which may have only provision for 10 memories.

Features include, scanning, the partial memory list, or any frequency

from that list, or part of the band, or you can adjust the time the

scan function pauses on a signal, and you can cut out noisy signals,

where the scan function would normally pause.

You can adjust the power output level to 1 Watt (X), 5 Watts (L),

10 Watts (M) or 25 Watts (H).

If a DTMF Microphone is connected to the display, DTMF can be added to

your transmission. You will need to check connections to the RJ45, 8V DC

is available on Pin 2 of the RJ45 to supply a DTMF encoder.

If the power is disconnected, the display will also remember the last

settings and reinstate's those settings on restart.

If a headset is used a headphone could be added from J13 to a headphone

socket on the escutcheon connection from the front RJ45 connection.

There is also an 3D printed escutcheon that Robert Patterson, ZL4ROB has

made to clip this kit to the front of the radio to finish off the

project.

If you need more info on the 3D escutheon, you can contact

him via QRZ

Programming the Tait 8100:

To make the interface work, the radio will need to be programmed

Initially to set the I/O ports on the DB15 socket, to send the right

signals to the display board. If you need to do this, see the

"programming info" link below on how to do it.

WARNING: You can do HARM if you don't know what

you are doing, so before you change anything here, seek advice FIRST.

Programming Info

Programming the Memory Channels and General Operation:

Download the manual and follow the operating instructions. Click on

the links below. The latest version is Ver 4.35

You should be running the lastest version.

You can also download the Full Operation Manual, and a Quick Guide.

I have added the latest version 4.35

Updates to the Program

Updates to the program were made, so if you are running version 4.32,

I recommend to upgrade to version 4.35.

To check what version you are running, when you first power up, the

VFO displays the version number.

To upgrade to this version, you will need to contact Keith ZL1BQE direct

or me via this website. He will either flash the your old IC or swop it

over. This IC is on a IC socket so it is easy to remove.

Download 3D VFO Case Front

You will need a 3D printer to print the case.

There are two types, one for a single VFO radio and the other for a

dual vfo version. The dual version would require two VFO kits and two

radio's.

Thanks to Rob ZL4ROB for the designing, of these 3D cases.

Notes on 3D Printing.

The files are in the later format .3mf

When printing either of these cases, print them to have the larger side

up as this will produce a better print. This can be confirmed by having

the writing up the correct way up when viewed in the printer.

Note that the writing is not shown when connected to the radio.

Print at 0.2mm layers and 20%+ infill.

Clicking on either of these links below will download the file direct to

your PC.

Download Single Head VFO Case .3mf file to PC.

Download Double Head VFO Case .3mf file to PC.

If you need .stl files, these would need to be converted to .stl

If you have any problem, please contact me.

Download Manual

You will need to click on the "links" below to download the manual

required.

Download Tait 8100 ver 4.32 Operation Manual to PC.

Download Tait 8100 ver 4.32 Quick Guide to PC.

Download Tait 8100 ver 4.35 Operation Manual to PC.

Download Tait 8100 ver 4.35 Quick Guide to PC.

Home Construction.

For those who are about to start building this kit at home, please

follow this step by step guide and that you read and pay attention to

these instructions, these are to help you assemble this kit.

I recommend that you read through these instructions first before you

start construction, as to pick up tips as you go and make construction

enjoyable.

Main Construction:

Before you start construction.

Refer to the parts list supplied. I would also recommend to read the

instructions below FIRST for construction tips and recommendations

BEFORE you

start assembling this kit.

Also if you need tips on soldering,

please see my

Solder Basics & Construction Tips

for further tips to help with the construction

of this project.

Failure to read these instructions may cause problems later

when the kit all comes together.

Once assembled, and you have any problem or issues see the

Trouble Shooting section below.

Unpacking the Kit.

When you receive your kit, I recommend to open the kit and put into a

click clack box or similar. This is so when you open the kit all the

parts will be in the box and will NOT get lost later.

In the kit is also a anti-static bag containing the 3x IC's U2, U3 and

U4 plus the 5v regulator U1. These are electrostatic sensitive devices

so handle these with care. I suggest you follow the ESD guide lines and

to use a wrist strap when installing these devices. Always leave these

ESD devices in the anti-static bag until you are ready to use them.

Search online for wrist straps for more information on this...

Sorting Components

First, prepare all the resistors as per the quantities in the parts

list, and sort them into there values.

I recommend that you use a

ohm meter and measure each resistor just to make sure you have the

correct value ready to install.

Only remove from the box the components you are going to install.

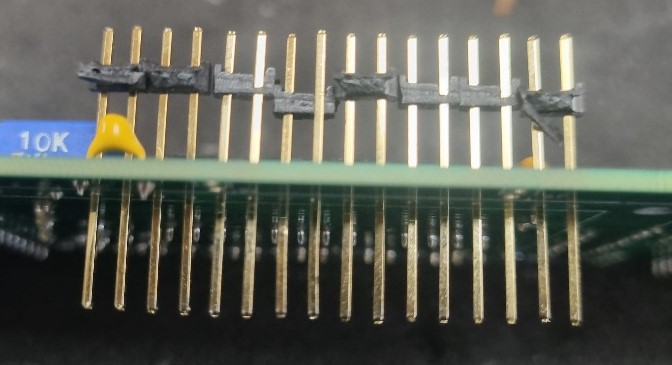

Construction Tips:

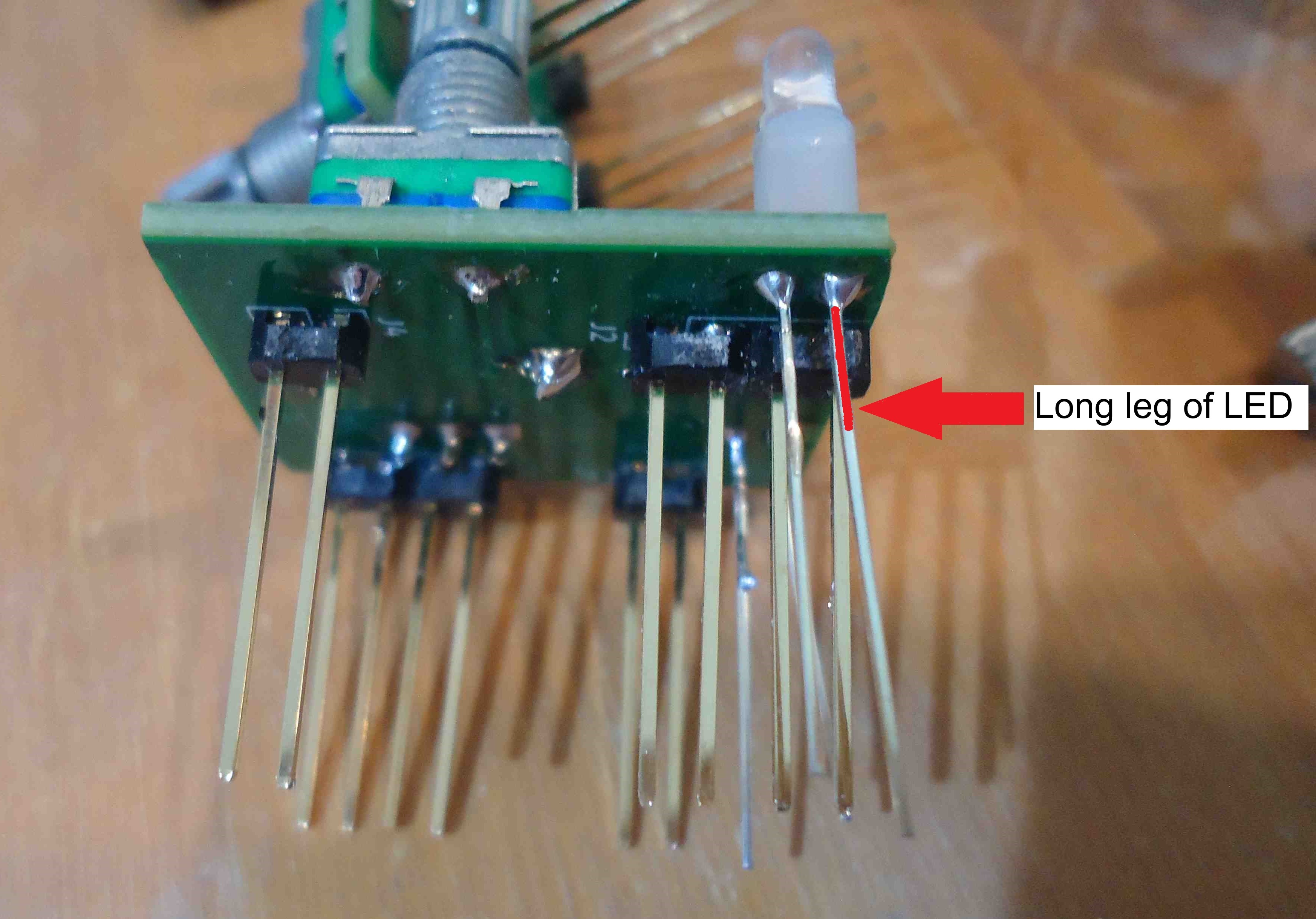

Photo 1. Shows the completed rotary encoder kit.

This kit has 1x PCB, 2x LED's and 1x rotary control and 6x sets of 2

header pins. 2x spacers for the LED's.

First look at photo 1, we are going to install the header pins. These

must be kept straight when you solder them. Insert all the pins onto

the board.

TIP: Using

the main board as a guide, place the main board flat on your work

surface and insert the pins on the board but DO NOT solder these pins to

the main board. This is only to align the pins and to keep the pins

straight while you assemble. Also these black spacers,will stop the

header pins from going all the way through the board and this would

prevent the rotary dial from being installed correctly. If spaced right

you will have just enough of the pin showing for you to solder, and the

rotary dial will be flat on the board when you come to install it.

Solder the header pins to the sub board so the pins are through the PCB

resting on the black spacer.

Now fit the rotary control to the board and make sure all of the legs

are installed through the board before you solder it. See photo 1. as

a reference.

Next fit the spacers to each of the LED's. These spacers have 2 holes

through them for the led pins. Once this is done, be careful and make

sure you fit them in correctly. Fitted one way round the LED is Red,

fitted the other way around the LED is Green. Looking at the LED, You

will notice one leg is longer than the other.

Fitting the LED's.

View the PCB from top side with rotary encoder facing you LED holes at

the top Left LED the long lead goes in to the hole with the round pad

the right LED, long lead of the LED goes into the Hole with the square

pad.

Alternately, looking again at photo 1, the LED top right D2 shows the

longer leg on the right hand side marked long leg. The other LED D1,

the long leg is fitted the other way round. This is very important as

the polarity matters to what colour is displayed.

Fit the LED's as shown in the photo and make sure the leds plus spacer

are all the way on to the board.

Trim the LED legs only once it has been checked.

This part of the kit is now complete and should look like the photo.

(The LED legs should be trimmed.)

Rotary Encoder Control Modification.

This part is found in the rotary encoder kit and this requires to be

modified. It has a small extrusion on the top part to stop rotation

of the encoder when mounted on a panel. (Shown below) This must be

removed as it is not needed.

Before.

Before.

After.

After.

The photo above shows the extrusion removed. A good pair of side

cutters can remove this and a small file for any burrs left. This will

now allow the control to sit flat once the front panel is fitted.

It is a lot easier to do this modification once this board is assembled.

Put to aside for now, this board is now complete and ready to be

installed later on to the main PCB.

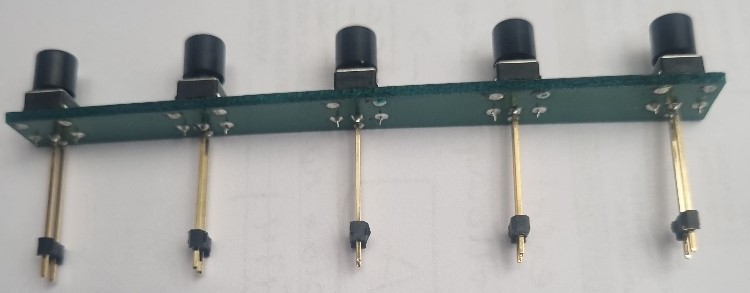

Photo 2. Shows the completed version of the push button kit.

This kit has 1 PCB board, 5x tact switches plus buttons and 5x sets of

2 header pins. To assemble this, we will put the header pins on first.

On the PCB board place the board with Keith's callsign ZL1BQE face down

flat on your work surface.

Install each header pin on the PCB with the spacer at the top. See

photo 2.

With the board flat, fit the header pins so they just go into the

PCB, and these header pins will be flush with the other side.

If you don't follow this step, the tact switches will not be flat

on the board when you go to install them.

Solder one side first and make sure the pins are straight, before

soldering the other side. Tip: It is easier to correct and straighten up

the pin with only one side soldered first. It is important these pins

are straight as this PCB will fit onto the main board later.

Do this for all five header pins.

READ THESE NEXT 2 STEPS BEFORE YOU SOLDER THE TACT SWITCHES.

- The tact switch MUST be flat on the PCB.

- Two pins of the tact switch needs to be trimmed before soldering.

Step 1:

First check in photo 2 to see which pins that are required to be soldered

and which 2 pins need to be trimmed.

The pins to solder first of the tact switch are either side of the

header pins. In the photo, you can clearly see two pins of the switch

are trimmed and lower.

When soldering make sure the tact switch is flat by soldering only one

pin first. correct this now if the switch is not flat. If ok, continue

to solder the next pin on the PCB.

Step 2:

You should have only two pins of the tact switch soldered. Cut and trim

the other two pins of the tact switch BEFORE you solder them. This is

so the two pins are even lower and do not touch the display once fully

assembled.

Once trimmed now solder them.

Do this for the other four switches.

If you did not follow these steps above and soldered all 4 pins, then

the display will come very close to the switches and possibly touch and

short out.

Put aside for now, this part of the kit is now complete and should look

like the photo. It will be installed on to the main PCB later.

Display Modification.

Click on this link for the instructions to modify the display.

After you click on the link below, it will open a new tab/window, so

once you have completed the modifications, simply close the tab to

return back here.

Display Modifications

Main Board Construction.

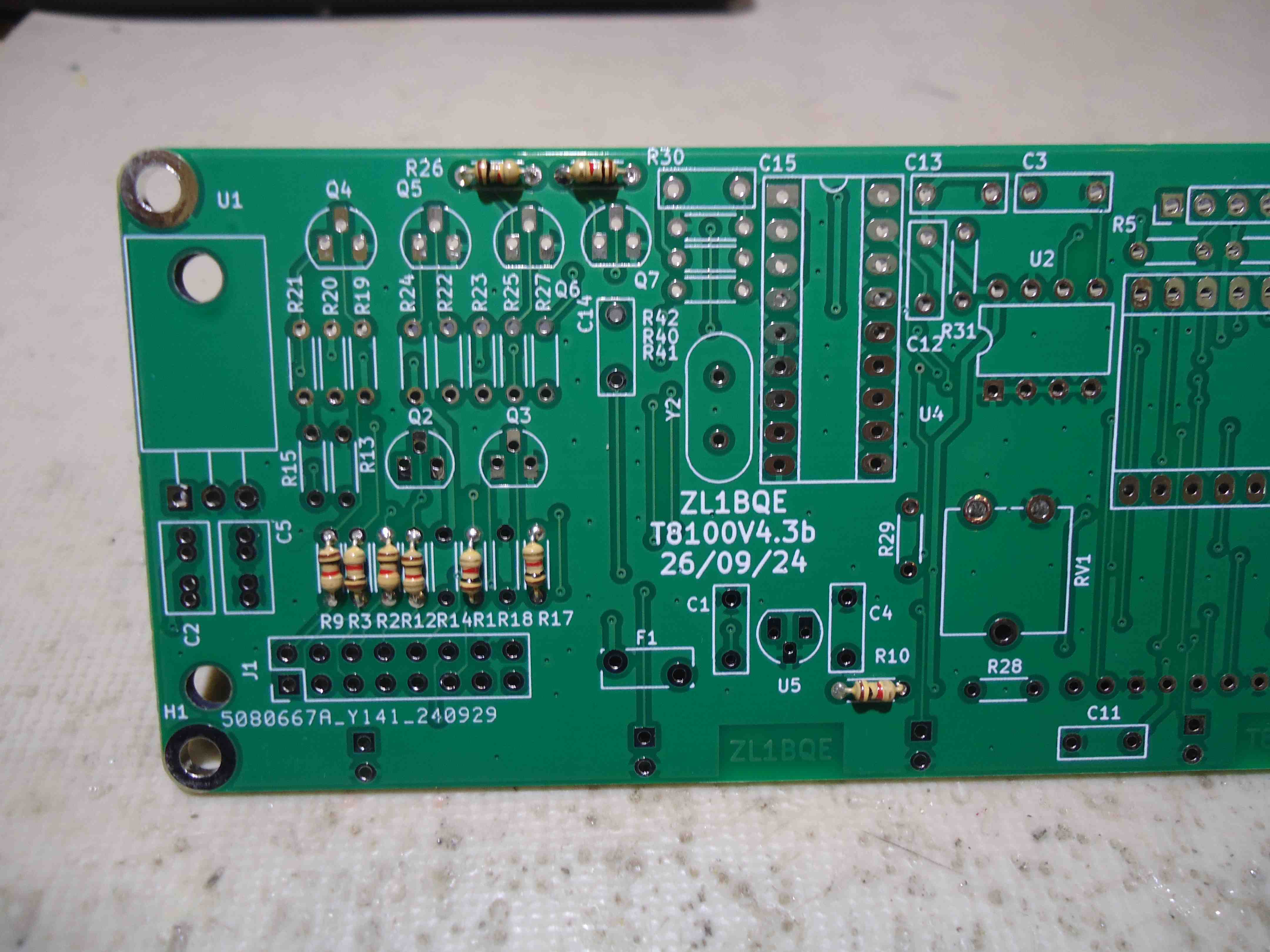

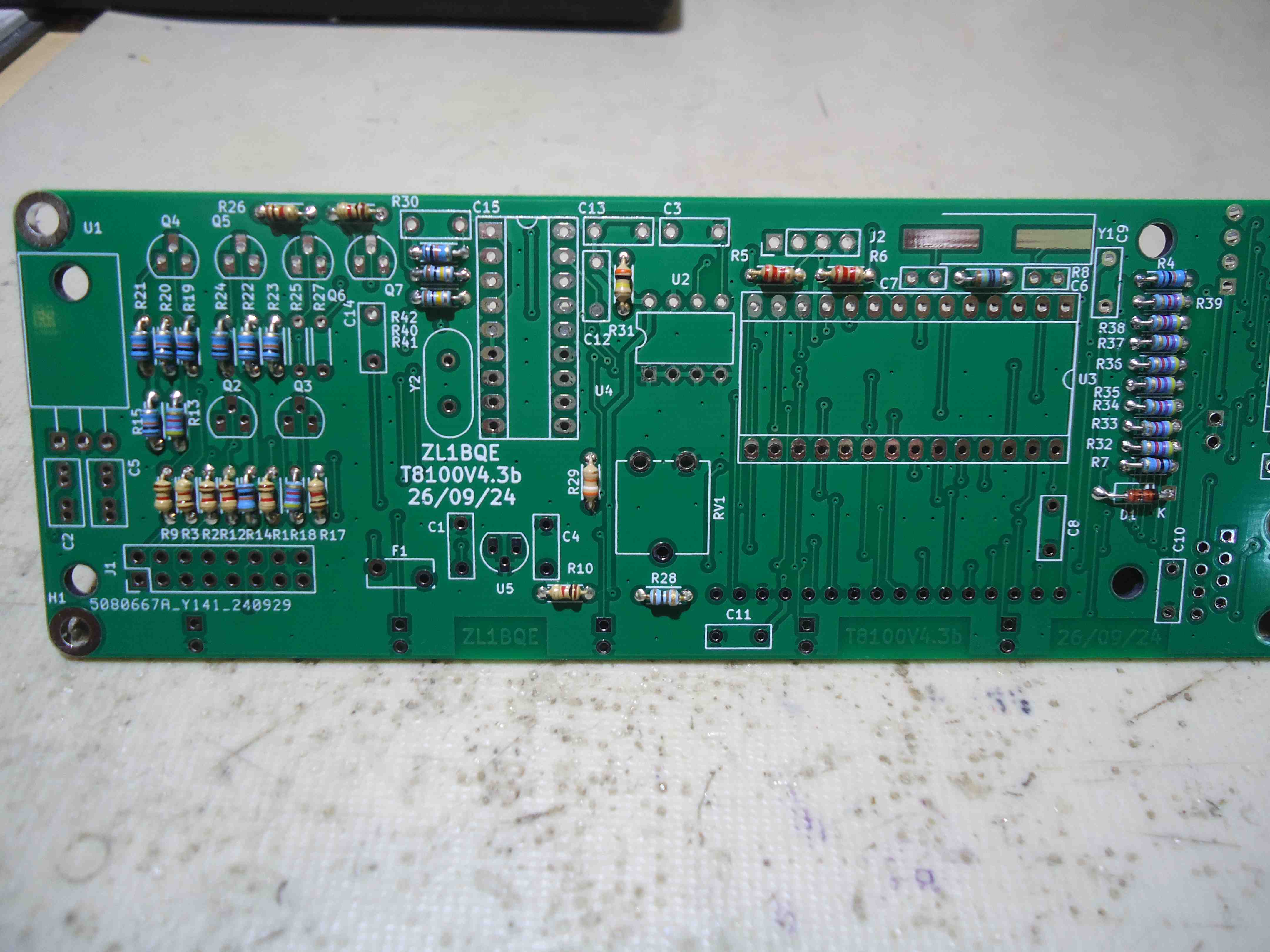

Photo 3. Shows the 1K resistors installed.

Start off by installing all the 1k resistors. (9 in total) These are R1,

R2, R3, R9, R10, R12, R17, R26, R30. Start soldering these in making

sure thay are flat on the PCB. You can install these a few at a time

until all 9 resistors are installed. After soldering, cut off the legs

close to the board.

Photo 4. Shows the 1K and 10K resistors installed.

Next install the 10K resistors. (11 in total) Again you can install and

solder a few at a time until all 11 of the 10K resistors are installed.

These are, R4, R7, R14, R15, R19, R20, R21, R22, R23, R24, R42.

When soldering these in and make sure they are flat on the PCB as you

go.

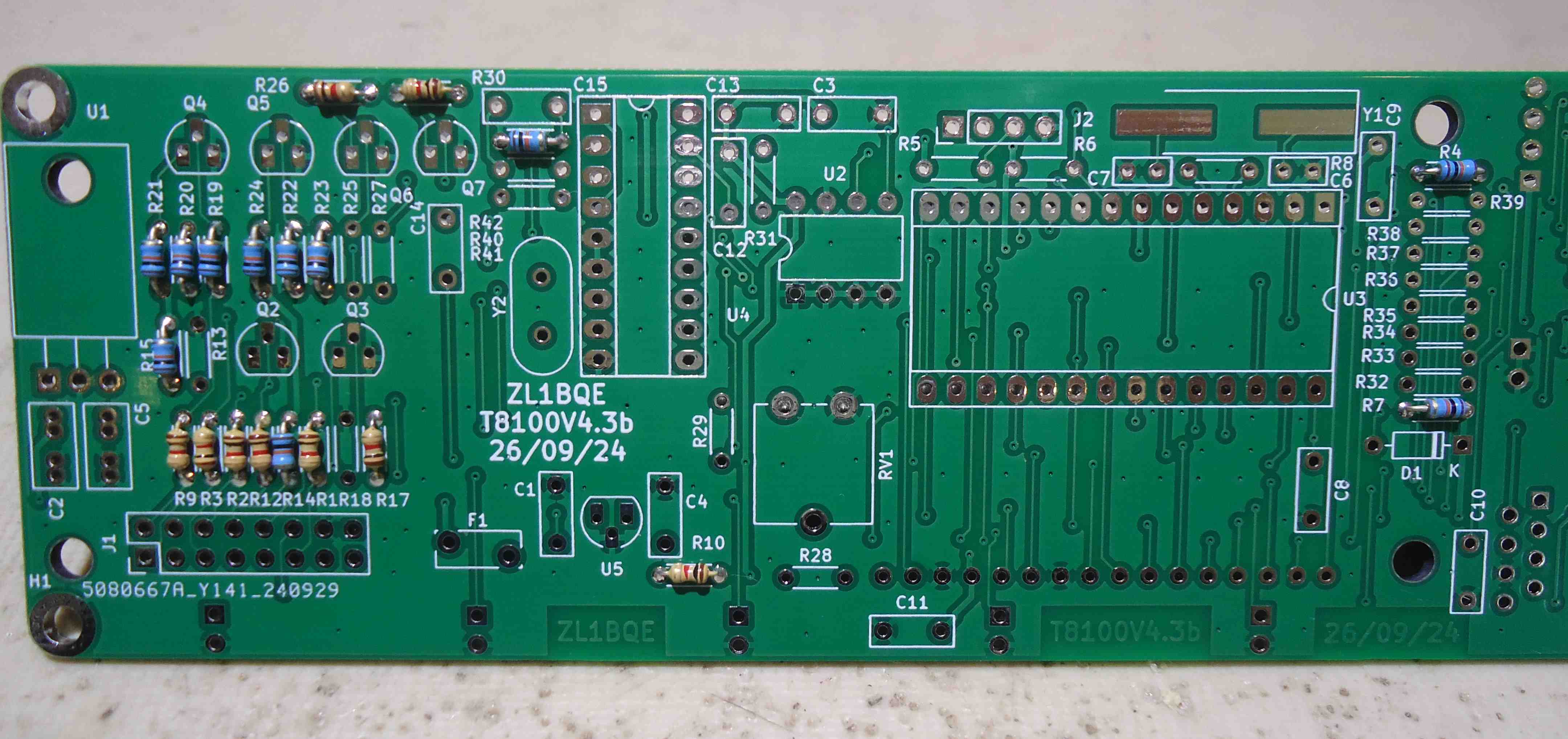

Photo 5. Shows the 1K, 10K & 4k7 resistors & Diode installed

Next, do the same for the 4K7 resistors, (10 in total) these are R13,

R18, R32, R33, R34, R35, R36, R37, R38, R39. Install the rest of the

resistors, there are two 2K2 resistors R5, R6. Then install two 47K

resistors R25, R27. Next Install two 100K resistors, R40 and R41.

Now Install the single value resistors, again making sure you install

the correct value resistor, as you can easily install the wrong value

resistors here, hence this is why it is best to measure them first.

Install the 100ohm, R28.

Next 33K resistor R29, This resistor is

listed as 39K but use the 33K resistor supplied.

Next install the

300K resistor R31, and the last resistor, the 1M resistor R8.

All the resistors should now be installed, as shown in Photo 5.

Note

R25 and R27 are not installed at the time this photo was taken.

Install the diode D1 making sure you get it around the correct way.

Looking at the diode, it shows a line at one end. This is the cathode

end of the diode. On the PCB, find D1's location and insert the diode.

The cathode is marked k. If unsure ask before soldering.

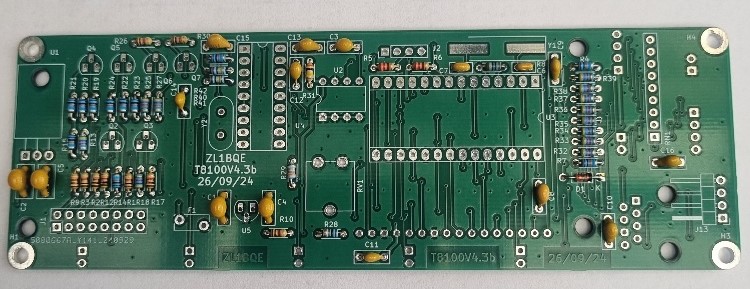

Photo 6. Installing the Capacitors

You can install these capacitors in any order. I would recommend to sort

them out into each of the values first, ready to install. I installed a

few at a time, soldering one leg first, then checking to make sure they

are fully seated and upright and trimming the legs once soldered.

Sorting the capacitors out first makes it a lot easier as you have now

identified what the value is and the quantity of each value.

It is good practice to install the same value capacitors as you go just

like you have done for the resistors.

I started first with reference C6 and C7, both 18pF.

Next to install I did C2 and C5 both are 10uF, and these are marked 106.

I next installed C1, C4 and C8, the 3x 1uF, these are marked 105.

next to install are the nine .1uF's, Reference C3, C9, C10, C11,

C12, C13, C14, C15, and C16. These are marked 104 on them.

With all the capacitors now installed, at this stage, your kit should

now look the same as photo 6

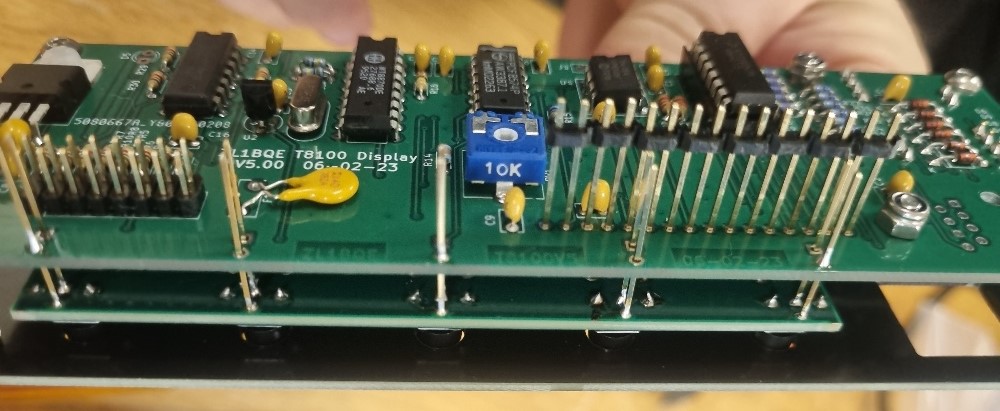

Photo 7. Installing the rest of components

Install the fuse F1. This needs to be bent over, see Photo 7. Next

install U1, L7805 5v voltage regulator. This needs to be bolted down

using the plastic nut and bolt. Install U5, MC78L08 8v voltage

regulator.

Check and install the correct way round, bending the

middle leg slightly, so once installed it lines up with the flat side of

the regulator to the flat side marked on the PCB. Push this down as far

as you can.

See photo 7.

Install the 6 transistors next. Q2, Q3, Q4, Q5, Q6 and Q7. These are all

BC547's.

On the PCB you will see the outline of the transistor. It shows a flat

edge and has 3 holes. You need to bend the middle leg slightly to fit

into the top hole and fit the transistor with the flat side, the same

on the PCB.

Install Y2 crystal, 3.57945Mhz. this is a through hole crystal.

Next install the SMD crystal Y1, 29.4912Mhz. When installing this,

solder one pad first, then align the crystal in the center of both pads.

Heat up the side you just tined, this will join the crystal and hold it

in place while you do the other side. Be careful not to apply too much

solder here as you do not want to get any solder on the crystal.

Install the 10K trim pot RV1,

Install the IC sockets U2, U3 and U4. Make sure these are

sitting flat when you install them.

When doing the IC sockets, solder one pin first, then solder the

opposite corner that you just soldered. Check it is still flat. Now

solder the other pins as the IC will no longer move. Do this for all 3

sockets. We will fit the IC's in once the main board is fully assembled.

Next install the multi resistor array RN1, (8x10K) Make sure this

is installed the correct way around. There is a dot which is pin 1.

Install J1, the 16 pin connector for the DB15 cable.

Install the J13 4 pin connector.

You now should have all components installed except for the RJ45 socket.

Do not install this yet as it is installed in the last steps.

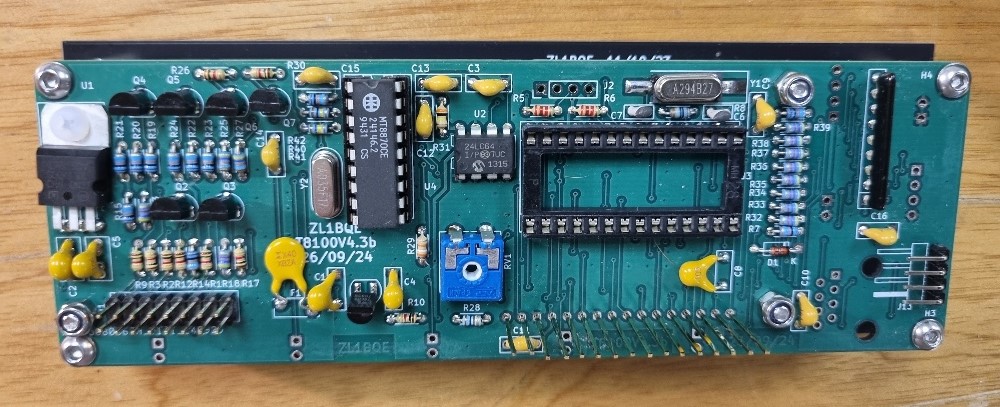

Assembly of the display and sub boards to the main board

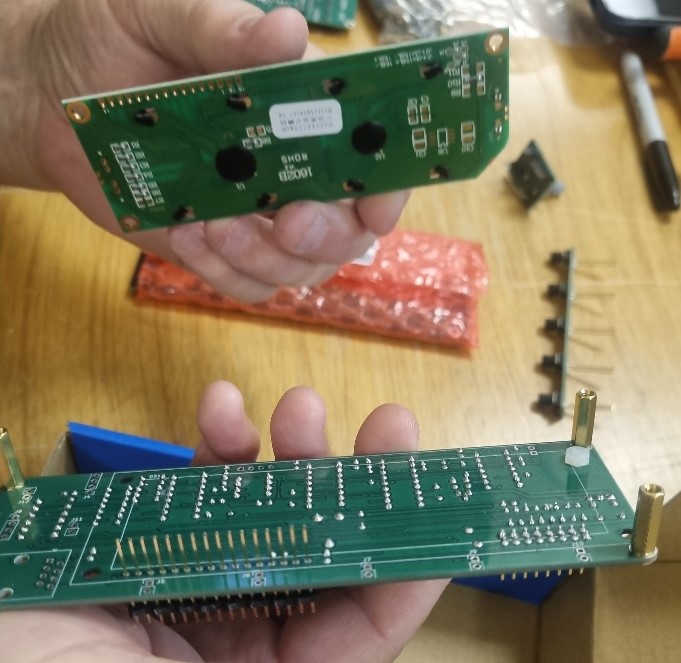

Photo 8. Installing the Header Pins

Fit the header pins onto the main board and push them in half way

through the board. as shown in Photo 8.

DO NOT solder these pins

to the main board. The push fit can be quite tight as the pins push

through the first time, carefully wiggle as you push them. The reason

why they are not soldered is that the length needs to be adjusted when

they pass through the display board, AND the tight push fit will allow

the display board to be removed in future if servicing is required.

Photo 9. Installing the Display on to the Header Pins

Make sure the display has been modified before fitting.

Next fit the four brass stand offs to the main board as shown in photo 9.

These brass stand offs will hold the front panel board once installed.

Next fit the display board onto the the header pins. Place the three

plastic spacers between the display and main board and then fit the

longer bolts through the display and fit the nylock nuts to hold down

the display. Tighten down but do not over tighten.

The header pins will be too long when fitted to the display as you can

see in photo 10.

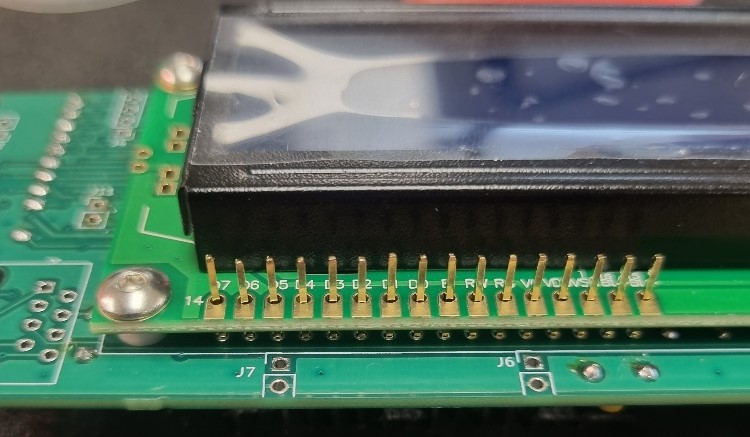

Photo 10. Showing the Display Installed on to the Header Pins

As these pins are too high and not yet soldered, it is easier to push

the header pins back down from the display side to almost flush with the

display, ready to solder.

Photo 11. Showing the Display's Header Pins ready to solder.

You can see in photo 11, the header pins have now been pushed back down

near flush on the display board allowing enough of the pins ready to be

soldered.

Photo 12. Soldering the Display Header Pins.

You can now

solder the header pins to the display PCB board top side

ONLY. There is no need to solder on the underside of the display

board as the connection is joined both sides anyway.

Turn the two boards over. The excess header pins will now be sticking

out of the main board. As noted in Photo 8,

DO NOT SOLDER THIS SIDE

TO THE MAIN PCB. By not soldering this end, it is to allow the

display board to be easily removed in future.

The tight push fit mimics a plug and socket connection and is sufficient

for the voltages and current to get through. Trim the excess pin length

to around 5mm sticking out from the main board. Once again remember

Do not solder these pins to the main board.

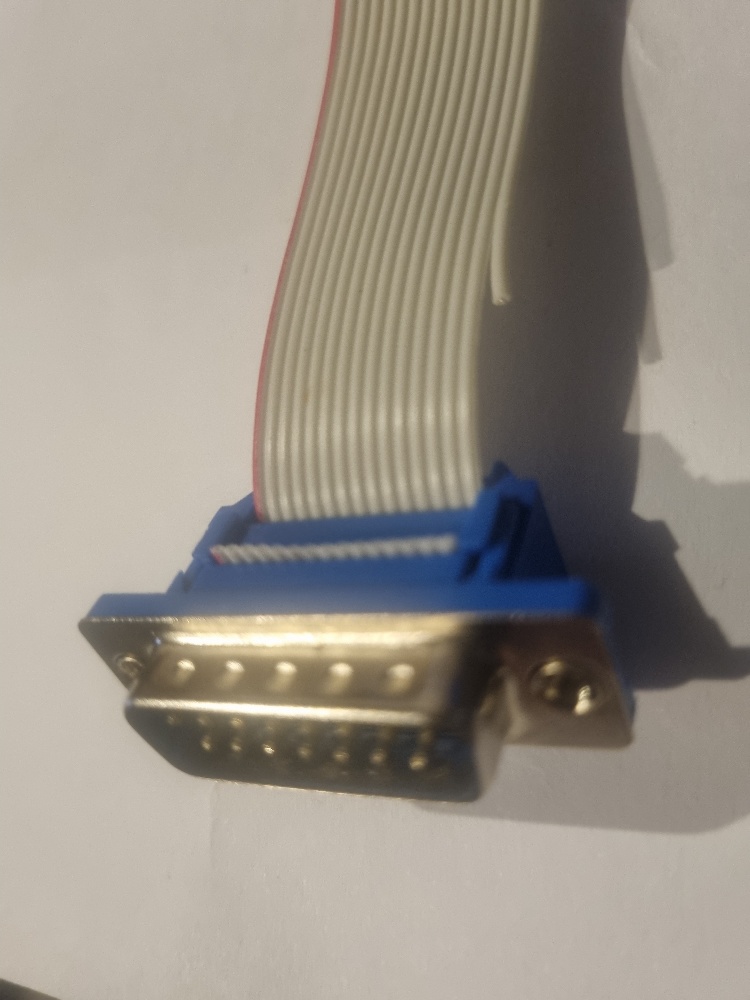

Making up the Ribbon Cable Lead.

Photo 13. Shows the 16 Pin Ribbon Cable.

In Photo 5, you can see pin 1 of the 16 pin socket. (Bottom LHS) Once

you fit J1, you can no longer see pin 1, but see photo 15 as this shows

the correct way round to fit the lead.

Fitting the wires to the Ribbon Cable.

On the cable, pin 1 is marked with the red trace.

As there are only 15 wires required on the DB15 connector, we need to

peel back the 16th wire and cut it off so it will fit the IDC connector.

You will need a small press like a mini vice to squash the connector

together.

Take care and DO NOT overtighten, otherwise you will

damage the connector. Photo 13 shows the lead cut and the correct way to

dress the ribbon cable onto the connector.

Testing the Display.

Before you continue to solder the rotary encoder PCB and push button

assembly in place onto the main board, you can power up the VFO using

the ribbon cable to your radio. This test will check if the display and

backlight is working Ok. You may need to adjust the trim pot RV1 for

contrast to light up the display. This adjustment will be almost at

maximum adjustment.

Any problems with the display or no backlight at this stage, Scroll down

to see the

Trouble Shooting section for details on how to fix.

Repeat this test (if necessary) and ONLY PROCEED, to the next step if

you see the blue backlight lit and the display is showing information up

on the screen.

Display Working

Continue to fit the rotary encoder PCB and push button assembly onto the

main board.

Photo 14. Fitting the Push Button PCB and Rotary Control PCB.

Fit and insert the button assy and rotary encoder PCB onto the main

board, before fitting the front panel. Do not solder these pins yet.

Align these header pins through on to the main board and now fit the

front panel.

Fit the display panel.

With the Display board and push switches fitted, fit the front panel

with the four screws.

Adjust the push buttons to your desired height and so you have the same

height for all the switches and solder only one pin first, on the left

hand side and one pin on the right hand side and finally one pin in the

middle. make sure all the push buttons are working and adjust if

necessary. Check that none of the push buttons are sticking, before you

solder the rest of the header pins of the push button assembly.

Carefully align the LED's through the front display and now pull up the

rotary encoder control so it is flush to the front panel.

I have already mentioned about cutting off the locating lug on the

rotary control and if you have not done this yet, this lug will cause

the control not to sit flush up against the front panel.

If you have done the modification, so the rotary control sits flush up

on the front panel, solder one of the header pins to the rotary control

board to the main board.

Check that the control is still flush up on to the front panel and once

ok, solder the rest of these header pins and trim the excess.

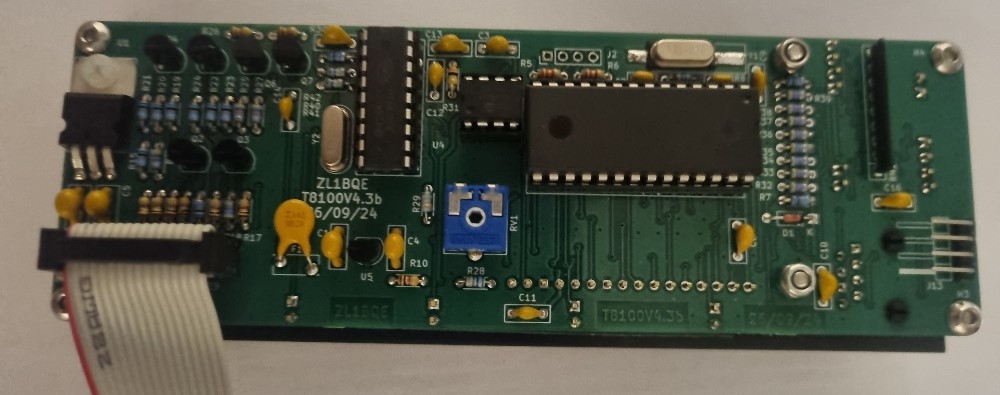

Photo 15. Completed PCB Component View.

This photo shows the completed PCB with all components populated except

for J3 the RJ45 connector. This will be the very last step to install

once the front panel is on and the window has been fitted.

Fitting the Window to the front Panel.

The display will still have the protected film over the display.

Do not remove just yet. You will need to make the window fit on to the

display front.

On a flat surface, size up the window and push in to the display.

It does need to be a tight fit, however if it does not fit in at first,

don't force it.

You may need to sand it down on the

edge that is oversized.

Not all the display windows require you to do

this and if it does, it will not need much to take off so be careful on

this next step.

To do this get some sandpaper and lay on a flat surface. Holding the

window, start filing the oversize edge, taking off a very small amount

at a time, checking each time you file off.

File each edge of the window until it press fits into the front panel.

Once the window fits in nice and tight, clean off any fingerprints from

the window, remove the front panel's 4 screws and remove the front panel

so you can now remove the protective film off the display. Refit the

front panel, then fit the RJ45 through the front display. This should

fall into place straight onto the board. Check before you solder, that

all the pins are into the board. Solder J3 once all is OK.

As this project is now fully assembled, you can now start to program the

radio.

Keep following the steps below and the link to download the

user manual to program the radio is found near the top of this article.

Ready to Turn On and powering up for the first time

Before you turn on...

See the troubleshooting section below if you encounter any issues.

Blue Screen only, No Text on Display

For the first inital power up, you may have only a blue screen with no

text. If you encounter this, then by adjusting RV1, on the main board

will bring up the text contrast. The adjustment of RV1 will almost be at

maximum.

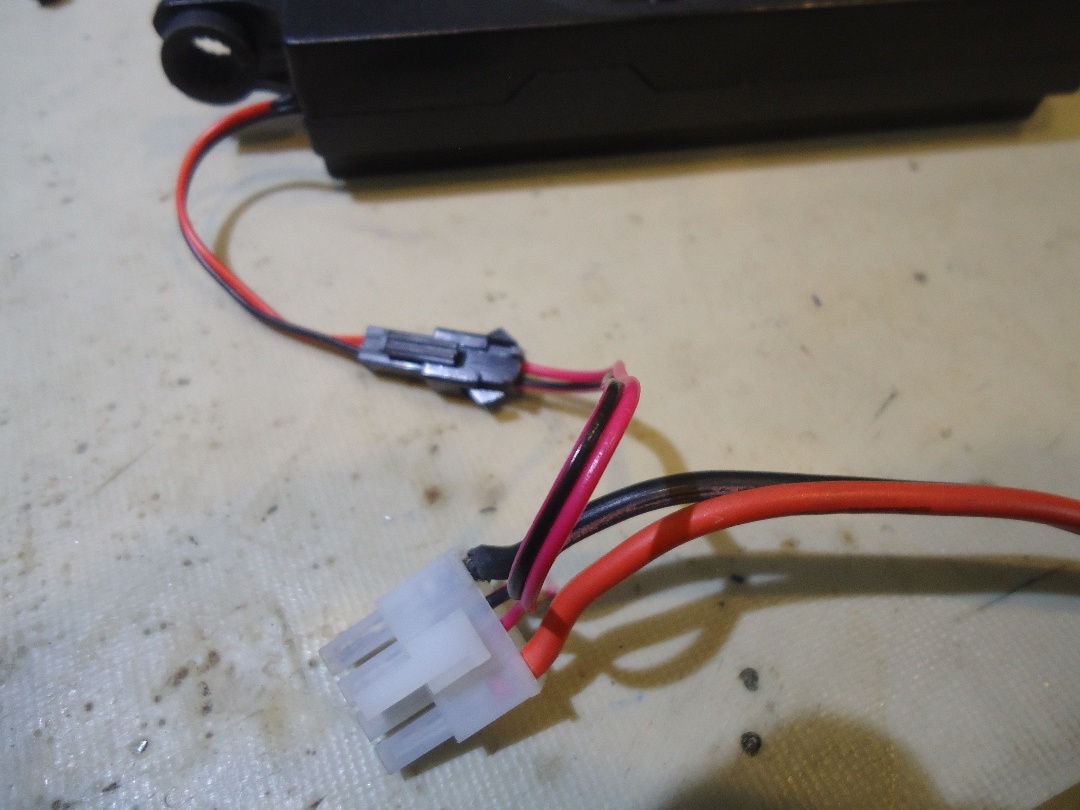

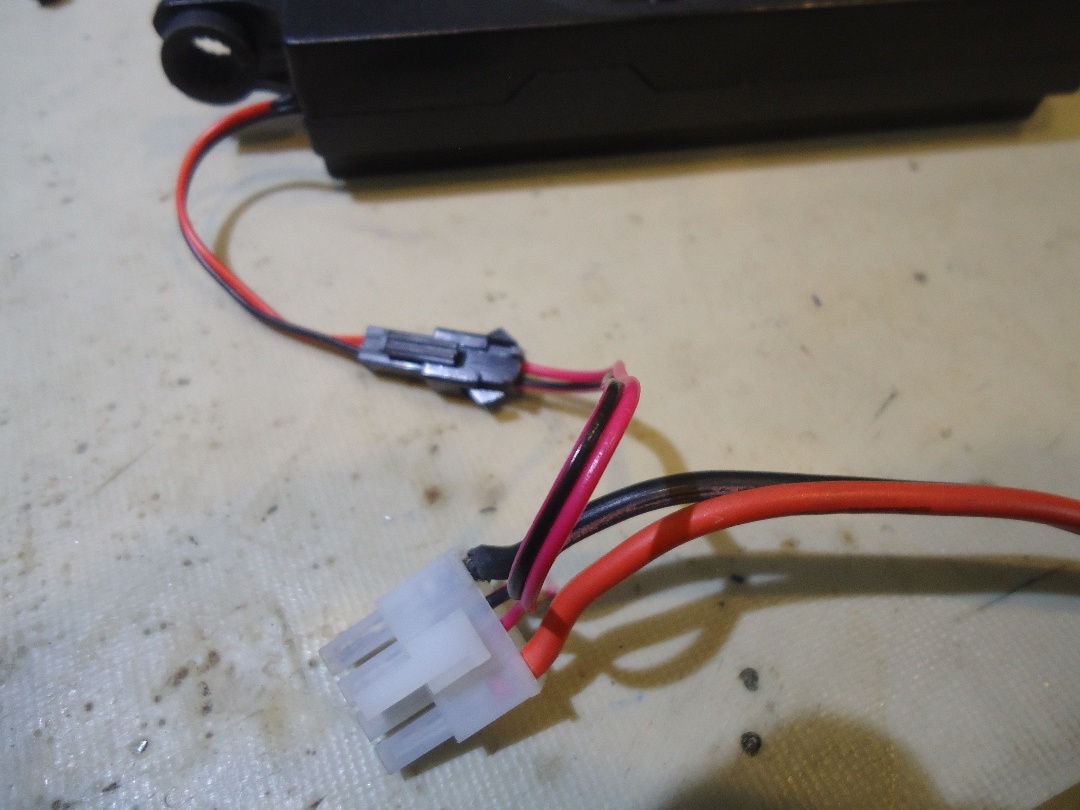

External Speaker

The radio will need an external speaker as the internal one was on the

original front panel and is no longer available.

The external speaker output is the two unused connections between the

power cable plug.(shown in the photo below)

If you do not have the plug and socket shown below, then an alternative

option is to use a inline 3.5mm mono socket on the speaker lead.

It is recommended to fit a plug and socket on your speaker lead as a

potential problem I see is the speaker is a balanced output and if any

lead is shorted to ground will damage the radio it would be good to have

a speaker with plugs on it. This means if you disconnect the speaker

there are no bare wires so this will prevent any damage mentioned above.

If you want to know more information or are interested about balanced /

unbalanced speaker outputs, see below.

If you were building this kit with the Papakura club, there were

speakers offered with the plug and socket, if you require a speaker,

there may still be a few left. The speaker does NOT come or supplied

with the kit if you have purchased online. Extra postage would be

required to send, but have limited stock on request.

Speaker Connection.

Speaker Connection.

The speaker pins, required for the speaker connection are M1561TL.

This is the Molex number.

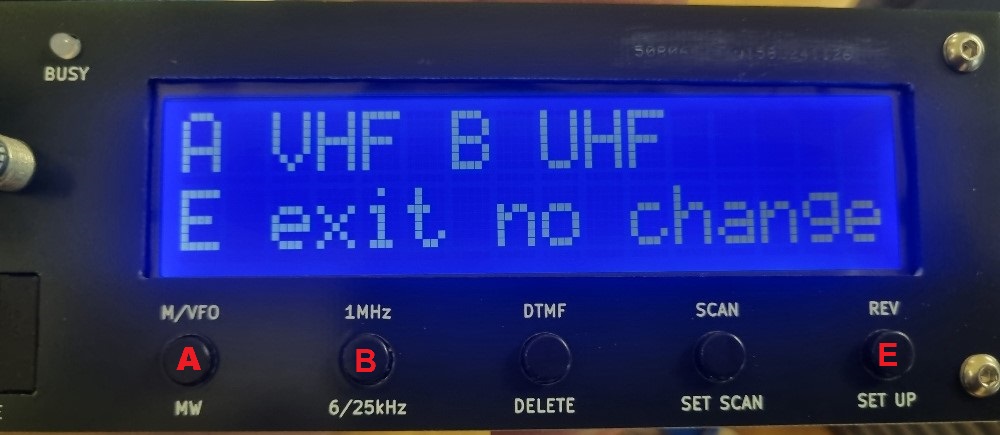

Photo 16. Shows the 1st Time start up.

When you get to this stage, you will need to select what version radio

you are using. VHF or UHF

Press the button marked A for VHF and B for UHF.

Once selected you then need to press B to accept your choice.

Press button E to exit for no change.

Once you have selected A or B the radio will power off. Turn it back on

by pressing the rotary control knob for 3 seconds.

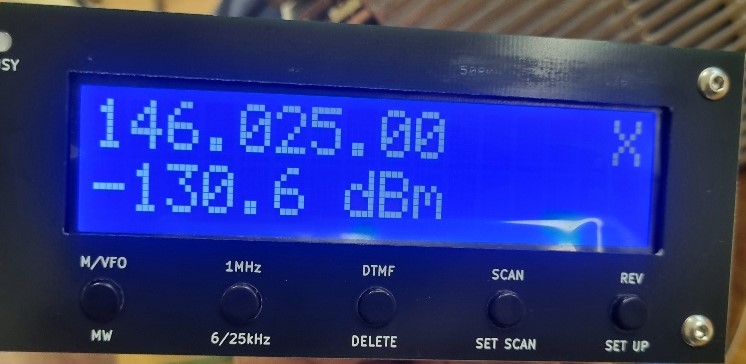

Photo 17

This photo showing the radio's display,

Top line is frequency and

power level X is Extra Low power (1 Watt)

Line 2 is signal strength in dBm

Photo 18. Shows the parts list

You can print this out if needed. Click on the link above the parts list

or print or save a copy.

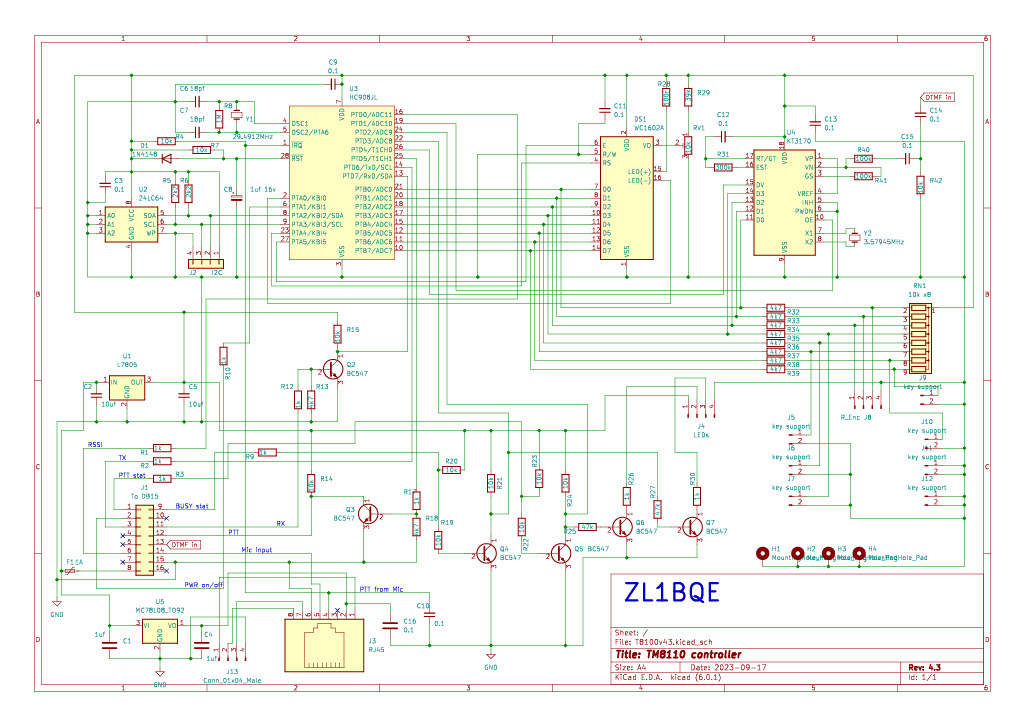

Photo 19. Shows the schematic diagram

This is the circuit diagram of the VFO Controller. Click on

the diagram or the link to show an enlarged circuit diagram. This will

open in another tab. simply close the tab when done and you will return

back to this page.

Balanced Output & Unbalanced Output Explained

If interested, here is some technical background on why you need to be

careful with audio circuits out of radios:

Unbalanced outputs – Most devices you use have what is known as

single ended or unbalanced outputs. An unbalanced output has a Ground

pin and a Signal pin. That means you can plug this type of output into

an external amplifier or other device that has power attached with

possibly a common Ground (negative) between the radio chassis and the

other device. This is OK for most consumer audio equipment but can be

problematic with radios as RF can circulate through the Ground

connections via a ‘Ground Loop’.

Balanced audio output – As the Tait uses a Balanced Audio Output

it avoids the Ground Loop problem. So, if you wish to connect the Tait

audio output to anything other than a standalone, insulated speaker, you

must use a transformer or capacitive coupling between the Tait radio and

the other device to isolate the audio amplifier in the radio from

Ground.

If you don’t, the radio circuitry may be damaged.

WARNING

You can do damage to your radio equipment, so before you do anything

or if you are unsure about what you are doing, ask for some guidance

FIRST.

Some more information – There is a lot of information

out there on the internet e.g. Check out this link below.

Balanced vs Unbalanced Connections.

PLEASE NOTE:

I have done my best to make sure this project goes together smoothly.

If you see any mistakes or I have missed a step or it is unclear to

please email me and let me know and I will add/edit or advise.

Trouble Shooting

As these are not in any order, please read all the trouble shooting tips.

No Sound

The radio will need and external speaker as the internal one was fitted

on the original front panel. This is no longer available.

NOTE: It is recommended to use a plug and socket for the external speaker

connection. Do not just use bare wires as if these wires touch or short

out, it will do damage to the radio. If you are not using the speaker

with the plug and socket mentioned above, then you can use an

alternative 3.5mm inline socket.

The connection for the external speaker is on the unused connections on

the power cable plug radio end.

The speaker pins, required are female M1561TL.

This is the Molex number for the pin. Fit an inline plug and socket on

the other end of the cable so that it will make it easier if you want to

remove the speaker.

Errors on Power Up.

Tait VFO 1st time power up

If the backlight is on but nothing displayed adjust the contrast control

on the back of the PCB to show initial display If the display shows

“Com Error” on 1st power on,

1. Power off by pushing and holding the rotary control knob

2. Power on by push and hold the DTMF button

3. Usually push button VFO for VHF and then 1MHz button for active

Volume control

The display will go off then power back on by pushing rotary control

knob this will reset radio to some defaults you will need to setup all

settings in the setup menu (Push and hold REV button to enter setup menu)

This error is due to the EEPROM contents set to “55” it should have been

erased which would set contents to “FF”

If EEPROM has been erased 1st power will go directly to VHF/UHF selection.

Refer to photo 16 to program the radio for VHF/UHF selection.

Once selected you then need to press B to accept your choice.

Blue Screen only, No Display

If you only have the backlight on, and showing a blue screen with no

info up on the screen, when you 1st power it up, you will need to adjust

RV1 the 10K trimpot. This pot should adjust the contrast up and start

showing the text up on the screen once you start turning the trimpot.

This adjustment will be almost at maximum adjustment.

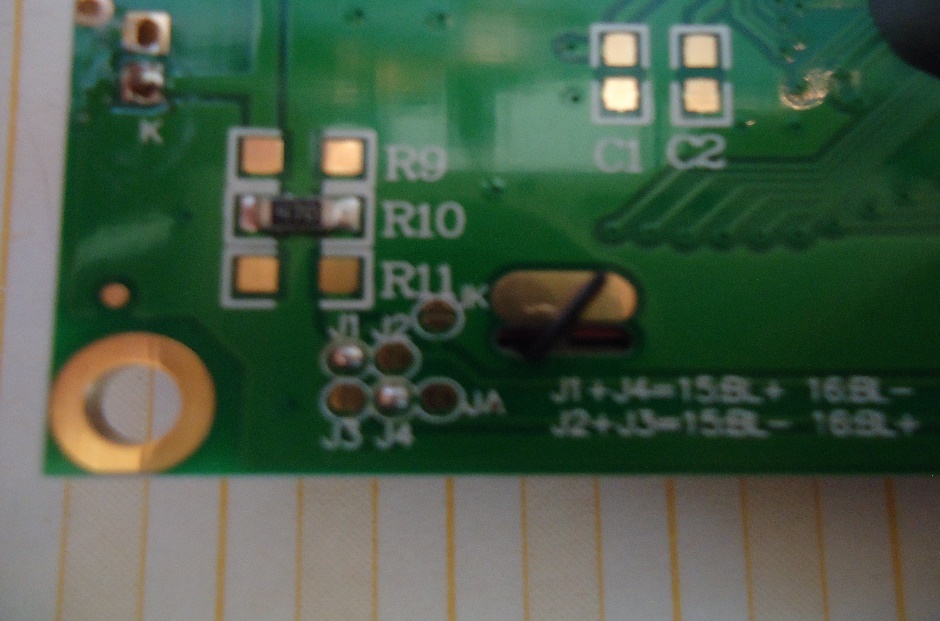

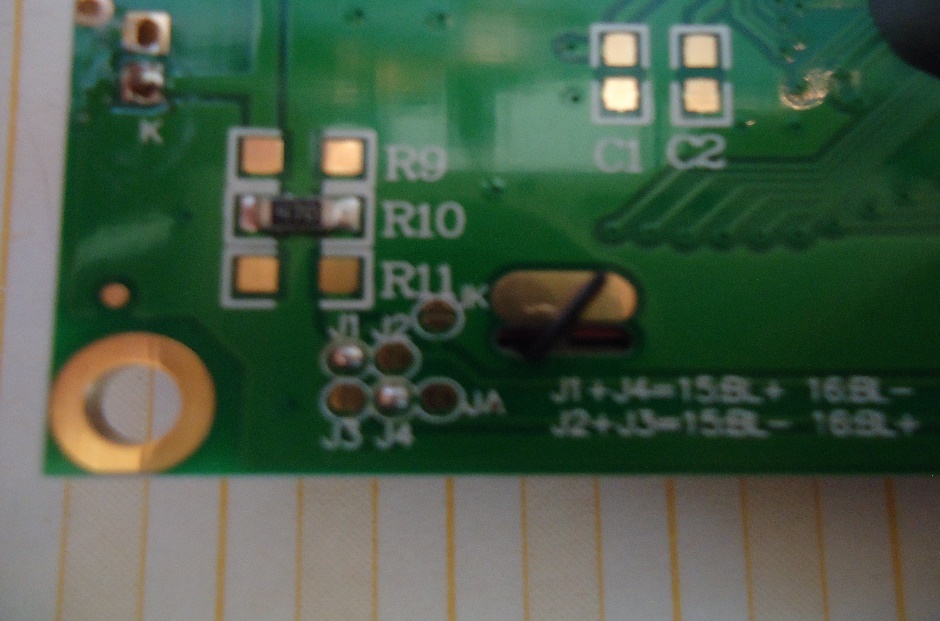

No Blue Backlight.

If the Backlight is not working then check the voltage on pin 15 of the

display, this should have 5V then check pin 16 should be 0V.

(Pin 15,16 are located towards the center of the PCB. See picture below

.)

Display Pin Numbers

Display Pin Numbers

Once the display board is running with some characters on the display

although very dim the voltages on the display should be 5V on pin 15 and

0V on Pin 16. If that is correct then the next thing to do is check the

links and if the backlight is still not working, then first check to see

the links are on J1 and J4. If correct try changing the links over to

the other combination. See photo below to change the links.

Links Changeover

Links Changeover

Only do this if you have no blue backlight.

links, 1 and 4 are correct links, BUT have found that some Displays

have the backlight diodes incorrectly assembled with the backlight

diodes reversed and if that is the case then links J2 and J3 should be

shorted J1 and J4 open.

NOTE

Only 2 link combinations should be connected at any ONE time.

J1 and

J4 linked with J2 and J3 open.

Pin 15 BL +5v, Pin 16 BL 0v

or

J2 and

J3 linked with J1 and J4 open. Pin 15 BL 0v,

Pin 16 BL +5v

Next Project Night.

Please go to the Papakura Info Page for further updates.

Papakura Radio Club Info Page

73 de Rob ZL1RJS

Latest Information.

As this has been a club project, some members have now completed the

construction of this project, and is fully working.

This is a step by step info guide, but if you are not sure of any of

the steps, then please ask for help and for now, please STOP and DO NOT

go any further until you are clear on what to do.

This is to ensure assembly of this kit is done correctly.

Photo 1. - The Completed Rotary Encoder Kit.

Photo 1. - The Completed Rotary Encoder Kit.

Photo 2. - The Completed Push Button Kit.

Photo 2. - The Completed Push Button Kit.

Photo 3. - All the 1K Resistors Installed.

Photo 3. - All the 1K Resistors Installed.

Photo 4. - All the 1K and 10K Resistors Installed.

Photo 4. - All the 1K and 10K Resistors Installed.

Photo 5. - All resistors Installed (except R25,R27)

Photo 5. - All resistors Installed (except R25,R27)

Photo 6. - Resistors and Capacitors Installed plus Diode D1

Photo 6. - Resistors and Capacitors Installed plus Diode D1

Photo 7. - Rest of the Components

Photo 7. - Rest of the Components

Photo 8. - Header Pins Install

Photo 8. - Header Pins Install

Photo 9. - Fit the 4x Brass Spacers and Display

Photo 9. - Fit the 4x Brass Spacers and Display

Photo 10. - Installed Display and high header pins

Photo 10. - Installed Display and high header pins

Photo 11. - Pins pushed down, Ready to Solder

Photo 11. - Pins pushed down, Ready to Solder

Photo 12. - Soldering The Display

Photo 12. - Soldering The Display

Photo 13. - Shows the 16 wire Ribbon Cable with only 15 Wires Used.

Photo 13. - Shows the 16 wire Ribbon Cable with only 15 Wires Used.

Photo 14. - Push Buttons Installed

Photo 14. - Push Buttons Installed

Photo 15. - Completed Component View .

Photo 15. - Completed Component View .

Photo 16. - Setting Radio VHF or UHF

Photo 16. - Setting Radio VHF or UHF

Photo 17. - Frequency Display and power level X (1 Watt) Signal strength in dBm

Photo 17. - Frequency Display and power level X (1 Watt) Signal strength in dBm

Before.

Before.

After.

After.